News

Search

Popular search

News Source:

Osram

Osram Opto Semiconductors (Osram) recently shared its insights on applications and developments in automotive lighting. According to the German semiconductor manufacturer, the future trend for automotive lighting will be OLEDs. Osram gives an in depth analysis of this future trend below:

Application: Automotive

Technology: LED

Target group: Consumer, Trade, Garage, Wholesale

LEDs are already standard for car lighting. The next technological development is on the starting blocks though with OLED. The major advantage of OLEDs: The technology offers completely new options for the design of light and luminaires.

LEDs are point light sources, whereas OLEDs are surface lights. Several lighting applications in cars – indicators, tail lamps or interior light – require wide-area illumination. The most significant challenge for OLEDs in automotive applications is thermal stability: To meet the requirements of manufacturers, OLEDs in tail lights for example must resist temperature peaks of at least 85 degrees Celsius. Last summer, OSRAM made a technological breakthrough in this area with the presentation of an OLED that could resist such high temperatures over several hundred hours as part of a long-term laboratory test. In the meantime, high temperature resistance has been improved to several thousand hours. “Following on from this research success, we are now tackling future use in series vehicles,” said Ulrich Eisele, responsible for the OLED segment at OSRAM. “The automotive sector plans and develops its future models with very long lead times,” said Eisele. “And this is why we have to be a part of this to help develop the cars of the future.” With OLED and with LED.

Three reasons as to why LED continues to be the technology of the times

Where in cars are LEDs plugged?

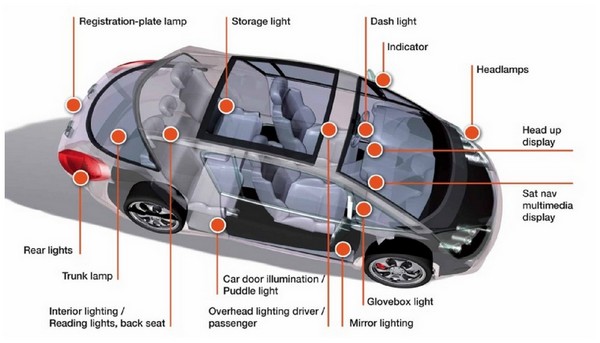

Osram points out areas in a car where LEDs can be installed. (Photo: Osram)

In terms of durability and toughness, high quality LEDs are superior to all other forms of lighting technology. LEDs manufactured by Opto Semiconductors (OS) operate in excess of 50,000 hours, meaning that light is more or less maintenance-free for the complete service life of a vehicle. This is one of the reasons why LED in car lighting is already the standard. More than 30 years ago in the initial stages of the technology, LEDs merely replaced very small incandescent lamps in car cockpits. Indicators in the tail section as well as tail lamps and brake lights were equipped with LED around 10 years ago, and daytime running lights later. Long life and robustness

All headlights with the Audi A8 illuminated for the first time completely with LED light in 2010, including dipped headlights, full-beam headlights, curve light and all-weather light. LEDs for interior and exterior lighting can now no longer be done without for the vehicle models of many other automotive manufacturers. LEDs from OSRAM are used in every second new vehicle.

LEDs are also environmentally friendly and energy-efficient: Automotive headlights based on LEDs require only 28.7 watts for each vehicle and for one light source, compared to 125.4 watts with halogen lamps – a saving of around 77 %. In this way, LED lighting reduces the consumption of fuel and helps towards lower CO2 emissions.

Modern light design

Why do customers buy one car and not the other? A decisive purchasing factor is its design. Thus companies make every effort to give their models a special “look”. “Light has become an essential element of design for automotive designers. Even in complete darkness, a brand-typical appearance should be recognized,” said Florian Rommen, Marketing Manager for Automotive Exterior LED at OS. Usually differing LEDs are used for the various applications (daytime running light, dipped beam, full beam, indicator) because of specific technical requirements.

But independent of LED type, all components are available in the same white groupings, giving them a seamless appearance. Another factor is that they can be similarly processed, allowing sophisticated design concepts to be carried out without much effort. In October 2012, OS presented the currently most compact high-power LED for the automotive market with its prototype of the Oslon Compact. “Because of the extremely compact construction and high light intensity, light points in headlights can now be configured more simply and also randomly,” said Rommen – the “design of light” of the vehicle takes on an unmistakable appearance, and new applications can be realized.

Safety

Because single LEDs can be aligned in tight sequence, decorative light strip solutions and also AFS (Adaptive Frontlighting System) applications are possible. Here the light of the front headlamps adapts to its surroundings: If another vehicle approaches, several LEDs in the headlamps switch off via intelligent control to avoid dazzling the oncoming traffic. A trend is also adapted lighting for interiors: Light sources inside the vehicle are dimmed on non-illuminated carriageways to avoid irritating other motorists and to simplify adaption of the driver’s eyes. Other motorists, pot holes and similar obstacles are identified earlier and more clearly, and the eyes of drivers are subject to less fatigue.